Research Lab captures significant cost savings and productivity gains

RIT APC Center for Packaging Innovation

Rochester, NY

Situation

Rochester Institute of Technology’s (RIT) APC Center for Packaging Innovation laboratory in Western New York, conducts cutting-edge projects targeting environmentally friendly and sustainable polymer systems. Through this work, they utilize a wide range of polymers such as LDPE, HDPE, PP, PBA, PHA, PLA and others. They also perform trials to recover polymer-based reclaim such as multi-layer packaging. Their goal being to advance knowledge in pursuit of sustainable packaging.

Joint collaboration between Dyna-Purge and the RIT team of Colby Armstrong, Tyler Reichert, Kunal Burarak led by Yvan Hernandez-Charpak, determined the current use of LDPE was both ineffective and inefficient for purging their twin-screw extrusion and blown film lines. Most often polymer residue or filler/additive contaminants were left in the process system. The RIT team led the effort to identify a more effective and efficient commercial purging product that could be used for purging transitions between trials as well as for safe start-up and shut-down operations.

Solution

They identified Dyna-Purge L grade – a newly developed compound, as ideal for their application and requirements. Conclusive trials confirmed their choice.

Results

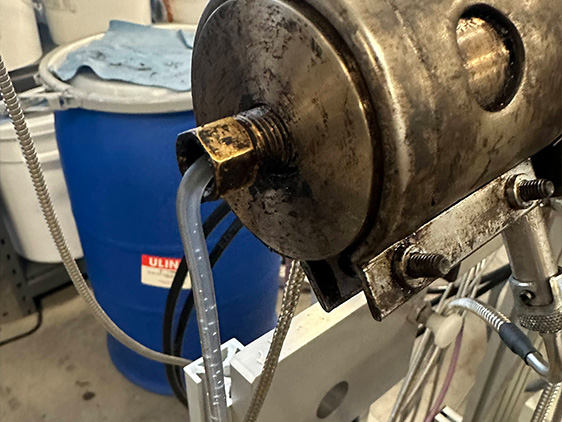

- Successfully achieved thorough cleaning of both their 20mm and 32mm compounding lines

- Material consumption calculation resulted in a 42% use reduction

- Downtime recovery calculation showed a 44% improvement

- Overall cost reduction calculation identified as much as 69% improvement with a 34% average improvement across all purging

The team from RIT

Mineral and proprietary sustainable fillers cause excessive carbon deposit

Extrusion trials with Dyna-Purge L-grade deliver a successful outcome.